| We finished a task from our house todo list! |

This week, the temporary stairs arrived. We worked on the isolation and moving planks. |

Isolating the walls of the ground floor,

Monday 20 July

The squash plant is thriving and making flower after flower. It is a delight to see.

The squash plant is thriving and making flower after flower. It is a delight to see.

Today we rethink the beams that we had placed yesterday. Yesterday we had not considered the height of a gypsum plate. With that in mind, we had to redo the bottom beams. Today we were thinking that it is easier to let the gypsum meet the ceiling, and since that means the bottom of the plates are almost perfectly matching the future height of the floor, that is the most natural solution.

At first, we had to find our ways on how to work and then slowly, but inevitably we found our way. My wife measured beams. I sawed and screwed them to the walls.

Tuesday 21 July

Today we were early at the new house because we would get the roof tiles today. The roof tile company quickly built their scaffold. They were much more efficient in doing this than we are with ours. Theirs is made of aluminum, and that makes it lighter, of course.

Today we were early at the new house because we would get the roof tiles today. The roof tile company quickly built their scaffold. They were much more efficient in doing this than we are with ours. Theirs is made of aluminum, and that makes it lighter, of course.

This went well until the roof tiles people discovered there was something wrong. They could not put up the tiles today. It is a bit technical, but the tiles we got delivered were not matching the bars on the roof. This is something that the builder and the roof tile company will sort with each other. The conclusion was that the scaffold should be taken down again.

But first, it was time for a break. The owner of the roof tile company had his birthday and treated us all on the cake. We sang happy birthday for him, and he was quite pleased, really.

But first, it was time for a break. The owner of the roof tile company had his birthday and treated us all on the cake. We sang happy birthday for him, and he was quite pleased, really.

He really wanted to convince us that we need a much bigger scaffold to be able to work correctly. I see what he means. He is correct, but renting one is not an option for us. I do want to add more items to the type we already got.

After coffee and cake, they broke off their scaffold and left the building site. We were on our own with our beams.

We put up beams, and we put up beams. Then again and again. There is absolutely nothing glamorous about it. It is repetitive and harsh work.

We put up beams, and we put up beams. Then again and again. There is absolutely nothing glamorous about it. It is repetitive and harsh work.

- On Sunday after lunch, we started on the beams task on the west wall of the living room. We got that wall finished around 4 PM on Monday. 14 hours.

- Then we continued with the north wall of the living room and the kitchen and finished that at 13 PM. 8 hours.

- Then we finished the washing room at 4 PM in three hours.

- The north side of the hall was finished at 6 PM in two hours.

The hands hurt. It is a lot of climbing up and down ladders.

A friend came to visit us, and she gave us an oak tree in a pot. A wonderful present!

Wednesday 22 July

There had to happen something to make the branch into a tree. I searched the Internet, and there they talked about water as well, but they said you could also just put the branch in soil. I was thinking that because it reacted so well to that glass of water, I would do that and keep the soil moisture. It is impossible to find out if a branch is developing roots when it is standing in soil. You could pull it out and conclude that, yes, it had roots, but they are now destroyed. What I did see without pulling it out was that the leaves died. That was no good. When all leaves had died, I thought I had to give it another chance. I pulled it out of the soil and cut off the lowest part of the branch. I did this with an angle so that there would be much surface. Then I put it back. That was two weeks ago. Now I have the first leaves. I so very much hope there will be more leaves. That would be so cool.

Anyway, we went to the plot and continued on the beams. The neighbor, Mr. AA, got his house delivered today. There were big machines and cranes. At Mrs. AB, they were busy with the exterior of the home, and at Mr. LB and Mr. RH, they were working on the foundation.

It did not go so quick with the beams today. I finished the north wall of the hobby room. Then I continued with the east wall of the hobby room. My wife started to put isolation material between the beams in the living room. That work is quicker.

We gave the plants water today.

Thursday 25 July

It is not a glamorous task we have set ourselves to do. Things did not go so smoothly today. The work on the house is tiring. Walking up and down on ladders. Drilling with the PZ2 screws. The four boxes of PZ2 screws is almost finished, it was necessary to buy new screws. This time we ordered T20, 4 by 70 mm with drill tips. T20 means that the head has a Torx shape of size 20. Do you remember that my brother in law had a top list of screw heads?

- Allen wrench

- Torx

- Pozidrive

- Philips

- Flat

On the first place on his list was Allen wrench screw heads, this is the best. The worst sort was flat. We advanced the top list one step!

To this, we also ordered bits, and this time we decided for extra-long bits. Long bits turned out to be the right decision because the head of the screws was slightly smaller, and sometimes the screw needs to be screwed into the beam a longer distance to really make sure that it is tight towards the wall. You can only do that if the bits are long enough.

Our son came and helped us today. It became a little unconcentrated with three people at the building site.

Friday 24 July

Today we took a detour to the building site. We drove past the scaffolding company. Outside they got boxes of scrap wood that people can take for free. We loaded as much as we could. I also talked to the owner about the possibility of buying more pieces to the scaffold we had. That is not so easy because it is not a common type, and he said that he had informed us about that, and that is true. I had not realized that I would become the only owner of a Crab 48 scaffold in the Netherlands. Others collect stamps while I collect the Crab 48 scaffold system. The dimension of the pipes in Crab is 48 mm. It was possible to connect the tubes with the help of generic connection points. It is even possible to get a tower of another scaffold type and bridge the two with the help of the generic cuffs and standard tubes. He also had bridges of aluminum that was 6 meters long. I will see if that could work.

The hobby room was completed yesterday evening. That is 16 hours, and today this morning, I started in the hall on the south side. It has several full-size windows from the floor and up almost to the ceiling. There is a little bit of a wall at the top of the windows.

Our squash is making flower after flower, it is delighted of how we treat it. The flowers are big and yellow, but they are difficult to see because they are in the middle of the plant between the leaves. In a way, they look like daylily flowers and also lasts one day, so that is very similar.

Our squash is making flower after flower, it is delighted of how we treat it. The flowers are big and yellow, but they are difficult to see because they are in the middle of the plant between the leaves. In a way, they look like daylily flowers and also lasts one day, so that is very similar.

Two of the pumpkin plants got eaten by a snail. One did not survive, but the other is working on a recovery. It is sending out new leaves.

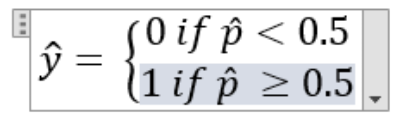

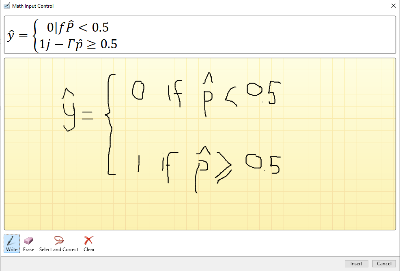

Here is a slide show of the status of the isolation work so far.

|

The south hall. |

|

|

Living room west wall. |

|

|

Here is the future kitchen, to the north. |

|

|

This is the south wall of the hobby room. See the self-made ladder in the corner! |

We talked about what we will do on the first floor. How the work will be done, but most importantly, how safe it will be to walk up and down on the ladder. I do not like the idea of working like that. I suggested building temporary stairs. My wife suggested we buy a temporary stair and that looked promising! It will be a little strange that we will enter the second floor via the wall to the bathroom, but that is the way it is.

Saturday 25 July

I started the day with blogging. I have been so tired in the evenings that I have had no energy for writing about the progress. This morning though, it was different. I was feeling much better. I think it has to do with the Torx screws. I need to use much less muscle power to avoid slipping screws. After a whole day of working, I spent much less energy on the Torx screws compared to the Pozidrive screws. The Torx can have the same problem, it is not so that they are totally free from this problem. They are less prone to that compared to the Pozidrive screws. I had to use force to avoid it while the Torx is more easy-going. I do understand that the Allen wrench heads are one step ahead, but I think they are also less convenient to mount on the bit. It is just a thought I have. Perhaps Torx is the compromise between Poxidrive and Allen wrench.

Today we finished the south wall. There is a little strip still missing, but for the rest, all outer walls on the ground floor are done. Tomorrow we will work on the inner walls. We will put isolation in them, and that is it. Perhaps we will figure out how to put gypsum plates on the inner walls, but that is it. We will need to keep them open until we had the electricity installed, and even then, there is still the thing with the ventilation to sort out.

I suppose we are working towards the general goal that we can have electricity installed. For that, we need to have the beams in place for the tubes holding the electricity wires. On the ground floor we got three different kinds of walls:

- It is the outer walls. These are delivered to us by the builder, sealed, and they are load-bearing walls. Right now, we finished isolating all the exterior walls.

- There are also inner load-bearing walls. All plates in the house are OSB plates. The internal load-bearing walls have OSB on one side, and they are open on the other side. OSB stands for oriented strands board. It looks like someone has been using shavings of wood in combination with glue to make boards. I suppose that is what it is. The shavings are 5 to 10 cm long (2 to 3 inches). This makes these boards, though, I think, compared to wood boards with smaller chips of wood. Because they are open, we can isolate them and then mount gypsum plates on both sides.

- Finally, there are inner walls with two sides open. That is actually just studs in a frame.

When we are finished, we have put gypsum around all wood surfaces inside the house. That makes the home more persistent against fire.

So right now, we finished the outer walls except one small strip. Tomorrow we will look into isolating inner load-bearing walls.

Sunday 26 July

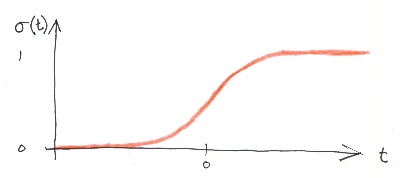

So how many liters of water per square meters had fallen into the bucket?

I measured there were 1900 milliliters of water in the bucket. That is 1.9 liters of water. The diameter of the bucket is 26 cm. That is 0.26 meters. It is important to calculate these things with the proper units. If we want to compare with liter and meters, then we need to convert to those units.

How large is the surface of the bucket, and what is the ratio compared to a square meter? The bucket has a radius of 0.13 meters. Let us assume the opening is a perfect circle. The surface is then pi times the radius2. That surface of the opening of the bucket then becomes 0.0531 square meters. So how much is that compared to a full square meter? That means we take 1 divided by 0.0531, and that is 18.83. There go 18.83 bucket openings in a square meter. Or, with other words, a square meter has 18.83 more surface than our bucket. So if we multiply our volume with 18.83, then we get how much that is measured in liters per square meter. I found there were 1.9 liters. So that gives that we had received 35.78 liters per square meter at our old home.

After long and tedious preparations, we finally got to work today. We had moved isolation of thickness 40 into the container and 80 into the house. The load-bearing walls should be filled with 80. We filled almost all standard walls. The work on that can continue tomorrow.

We also had a look at the planks that we have stored outside the container. We moved this stack of planks here on 12 July. We concluded this was not a good idea, after all. It was wet. Especially after raining yesterday. We decided that we will move these planks inside as well. Not today, though. It will be almost dry for a long time now, so we decided to open up the package we made so that the planks can dry. Then in a couple of days, we will move the planks inside the container.

Tonight we ordered a temporary stair building kit. We ordered it to be delivered to the new house. It is a simple straight stair that we can have to walk up to the first floor. We designed the house to have a stair that curves around a corner, but we will order that stair when most of the building activities are finished. The idea is that it will be safer to work upstairs when we have a real stair, although simple. Walking up and down on ladders between the floors is not an excellent idea. I will also build a fence around the staircase.

This concludes our first full week of building holidays.

Started insulating the barnStarted putting up planks on the north wallTried to get InternetWastewater and RainwaterWorking on the exterior this weekWe planted our apple treesStarted on ventilationMoved a pile of floorboardsWe are getting better at the gypsum platesElectricity and waterPipes and powerlinesEverything worked this weekRoof tiles and gutter finishedWe got our temporary woodstoveFinished horizontal support beams on the east side

Started insulating the barnStarted putting up planks on the north wallTried to get InternetWastewater and RainwaterWorking on the exterior this weekWe planted our apple treesStarted on ventilationMoved a pile of floorboardsWe are getting better at the gypsum platesElectricity and waterPipes and powerlinesEverything worked this weekRoof tiles and gutter finishedWe got our temporary woodstoveFinished horizontal support beams on the east side I moved from Sweden to The Netherlands in 1995.

I moved from Sweden to The Netherlands in 1995.

Here on this site, you find my creations because that is what I do. I create.