| Received the construction drawings today |

Learning Machine Learning and Artificial Intelligence, Part 1 |

Repair a bike using Excel

It is Saturday 31 August 2019, and I am taking on to repair a bike I got for cheap. The bike is fine except for one thing, the front wheel is not round anymore. The previous owner gave me a nice price because he had bumped into the sidewalk, so the front wheel was not perfectly round anymore. I tried the bike, and it was awful. There was a considerable bump in the rim.

For this repair project got a high-tech plan. I decided to measure the wheel and make shims with my 3D printer so that the weel becomes round. I think it is an excellent idea.

The first thing I will do is to find out how much the error is. To do this, I turned the bike upside down. Then I placed a wood beam along with the bike so that I could mount the caliper at the front wheel. I duck taped the wooden beam. Duck tape was not good enough, but I did not know that until later, when looking at the data.

It is going to be interesting to see what the difference is!

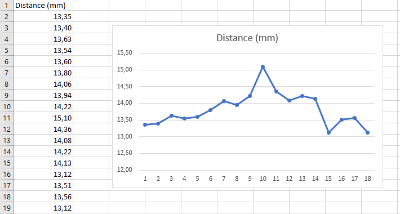

Around the wheel, I wrote numbers on the aluminum rim, and then I measured the distance with the help of the digital caliper to the wheel all-around at all the measuring points.

At 15 and 18 the wheel has the maximum radius, and at point 10 the wheel has the minimum radius. There was a two millimeters difference in the radius. That gives an unpleasant ride.

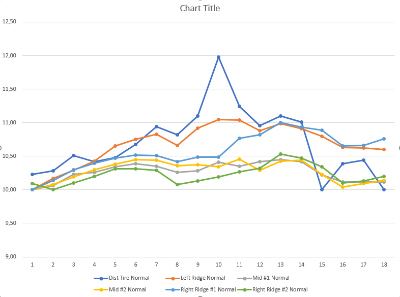

Now I remove the tire and then I will see how the error is on the rim. I renamed the Distance into Distance tire. Then I added a few more columns for measurements to the aluminum.

I measured the aluminum in five places. Then I normalized the values as if the caliper was exactly 10 mm from the minimum value of each series. This way I can put them in a graph and compare them.

I see a correlation between the tire and the left ridge. Unfortunately, I measured the left ridge only once.

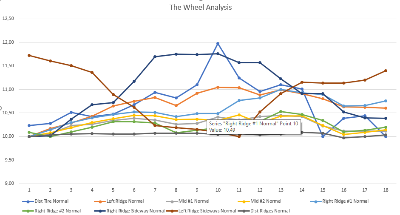

While entering the data, I started wondering if there is perhaps an issue sideways and not so much along the radius. The tire needs to fit into the space between the ridges. If that space contracts sideways, then there is much less room for the tire, and it will pop out and cause a bump. So I need to try this theory and measure the sideways differences.

I am looking at the data, and it does not make sense. The distance between the ridges is the grey line, there is absolutely no problem. The light blue and the orange lines show there is something wrong with my way of measuring. It is a wheel, so the measurements at point 1 should line up with the measurements at point 18. They don’t. Perhaps the duck tape I am using to fasten the beam is not ridged enough so that things start bending while measuring.

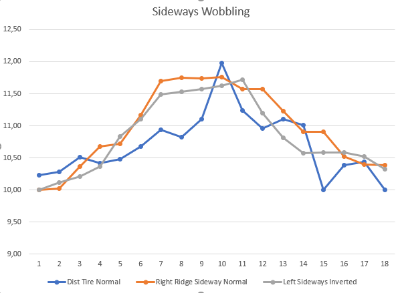

You can see that the wheel is wobbling sideways from the red and the dark blue line. I measured these in opposite directions, but actually they are wobbling equally. To show this I inverted the left side as if it was measured the same direction as the right side.

I included the distance to the tire as well, but I cannot understand that the wobbling is causing the bump.

The wheel is not perfectly round, but the aluminum is round enough. So what kind of mystery is this?

I had a look at the tire to come up with new ideas about the problem, and then I noticed something.

Can it be so that the tape that should protect the tire from the spokes bolts has slid too much upon the side of the rim so that the tire doesn’t get a proper grip on the rim and bulges out?

This is at point 11 on the wheel, so that is a perfect match.

Sunday, September 1, 2019

Yesterday I put the tire on, and I was hopeful that I found the problem and that now everything would be fine. But that was not the case. There is still a bump in the tire.

I made a mistake when I took off the tire. I left no mark on it to show how it was mounted on the rim. Now the tire is back on but perhaps on a new place. I will measure the bump again. So I went outside in the garden where the bike was, and I looked at the wheel.

The tire has reflections along the side and where the “new bump” was the line of the reflective material deviated inwards to the center of the wheel. I realized that the new bump was no bump anymore, but a hole and this coincided with the deviation of the reflective line. What can possibly cause this? Is there too much rubber on the tire at that spot, or is there more of the red duck tape sliding around or is it both?

Took off the wheel, looked inside and decided to cut away more of the red duck tape. I also cut away a little thin strip rubber of the tire.

Then I put it all back and inflated the tire. I could hear distinctive “knack” when the tire fell into the correct position. IT WORKED!

So with this, I got myself a well-functioning bike! I did not get to use my 3D printer, but that is fine.

I moved from Sweden to The Netherlands in 1995.

I moved from Sweden to The Netherlands in 1995.

Here on this site, you find my creations because that is what I do. I create.