| Ready for the floors |

This week wet room floors were cast in cement |

The anhydrite floor

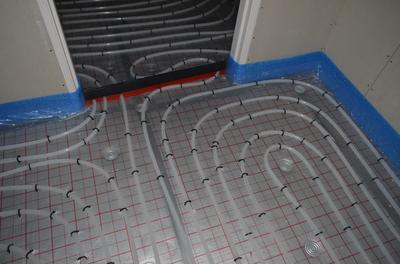

This week the floor-heating pipes were laid out on our floors, and then the pipes were cast in anhydrite. The blog this week is exceptionally long. I have no idea how that happened.

Monday 1 November

Monday 1 November

This morning I got a little help from a colleague enabling me to let in the floor heating people. I parked on the dirt road so that the people could drive up to the house as far as they wished.

They arrived perfectly on time. Behind the car, they had a trailer with isolation material. I showed them around, and they were delighted with the preparations we had done. They were also happy that we arranged a coffee corner in the workshop, although it must be removed when ready to prepare. The idea is that happy people provide a better job. I explained what cable was serving the sheep so that they should not remove that cable. They were not keen on gathering loose sheep together, so they ensured it stayed in the outlet.

They arrived perfectly on time. Behind the car, they had a trailer with isolation material. I showed them around, and they were delighted with the preparations we had done. They were also happy that we arranged a coffee corner in the workshop, although it must be removed when ready to prepare. The idea is that happy people provide a better job. I explained what cable was serving the sheep so that they should not remove that cable. They were not keen on gathering loose sheep together, so they ensured it stayed in the outlet.

Then I went to our old home and started working. It was a full day of work after our DIY holiday last week. Started by reading emails and got started with my office work. At the end of the day, we went to the new house to see what the floor heating people had produced today.

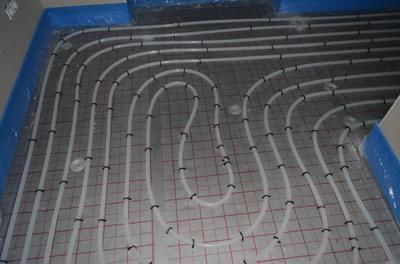

It was a little dark already, so it is not the best of the photos, but the kitchen with the pipes already laid out. The blue thing to the left is the floor box.

It was a little dark already, so it is not the best of the photos, but the kitchen with the pipes already laid out. The blue thing to the left is the floor box.

They had hung up the ladder to the first floor! Ingenious solution. Now it can be standing there in its own bucket without disturbing the cables to be laid out below it, and at the same time, they can reach the first floor. They had hung up the distributors on the wall in the utility room as well. It is from this place the pipes will be fed into the house.

They had hung up the ladder to the first floor! Ingenious solution. Now it can be standing there in its own bucket without disturbing the cables to be laid out below it, and at the same time, they can reach the first floor. They had hung up the distributors on the wall in the utility room as well. It is from this place the pipes will be fed into the house.

They had also started the preparations on the first floor. The same isolation material with a grid pattern, but it was not as thick.

We gave our sheep their food supplement, and then we went to our old home. There was not so much to do in the new house.

At our old home, I was called by Gijs, who will install the heater. He can come on 22 November to install the system so that the heating can be turned on. I need to make sure the tiles are finished in the utility room before that date. For that, I have to talk to our tiles person. Would it not be nice if all this were just arranged for me that I just had to sit and wait patiently until the house was ready to move in? If we wanted that, we had to have a completely different house. For example, a house out of a catalog made of brick stones. It had been much smaller because we would not be able to pay for it. The price of the house had been so high that we probably would not buy so much land either. Suddenly from one thing to another, the situation had been totally different. No, we take it like this.

Tuesday 2 November

I feel it is sometimes a little challenging to get back to total concentration after a holiday. I finished two big tasks today at work, but I was not feeling back to work in my head. Nevertheless, two good things were done. It will get better from here.

It was a gray, dull day. I do like it when the sun is shining, even if I am indoors. I know other people get annoyed when it is beautiful weather outside when they have to be inside, but I don't have any issue with that.

Danny laying out the pipes called me today to ask me how he should do around the woodstove. Luckily I had left the temporary foundation stones outside. He found them and put them back as a template to put the pipes around the woodstove and not under the woodstove.

We gave the sheep their food supplement, and then we went back to our old home again.

Wednesday 3 November

Today I worked half day. It was sunny but also misty from time to time and not especially warm. At lunchtime, we first went to a flooring shop where they were selling PVC floors. We were introduced to the world of PVC flooring. We decided on some kind of wood pattern and tiles that will get glued to the floor. It will be necessary to equalize the floor before putting in the tiles. Instead of making a decision of exactly what tile to buy, we got two samples with us.

I talked about PVC before 8 January. It is a fantastic product but has two bad characteristics:

- It is made out of fossil fuel, bringing the world to climate catastrophe

- It contains chloride. When burned, this is rereleased, and it will cause dyspnea, violent cough, nausea, vomiting, lightheadedness, headache, chest pain, abdominal discomfort, and corneal burns.

But these floor tiles are soft, unlike the downpipes I talked about last time. What has been added to make them soft?

Until a few years ago, phthalates were added to the PVC to make it flexible. This substance is not healthy for humans. It appears that these days the phthalates are replaced with a better substance. I will ask for this from the flooring company next time. This time I forgot to ask this.

I will also ask them if they send local people to work in our house or send people from eastern Europe. It is not morally right for me to be part of a modern sort of slavery. We have neighbors that had low-cost employees working for them, but up until now, we avoided that. Also, I don't think it is suitable for the climate having people travel a long distance to work underpaid.

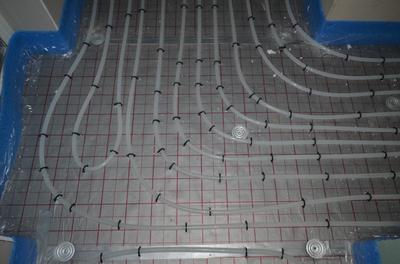

We went to the new house. We had a chat with the people laying out pipes. They were full-on busy in the house. They are friendly people, charming to have them working in our house. They finished the ground floor today and started with the pipes on the first floor.

They told us they had to put in shorter circuits since we wanted to cool with this system. Usually, one circuit would be 120 meters, but we had around 80 meters circuits. The total length of pipes in the house will be 1800 meters of pipe. They divided the house into smaller sections, about two by three meters depending on the exact place. A section has a feeding line lying directly next to the exhaust line. That way, there is always a hot lying next to a cold pipe on the floor.

We started on our project for today, building a hay rack for feeding our sheep with hay. We used a couple of old pallets and some rest planks from the wood facade of our house. The lid plate was a rest piece that I got from thrown away building material of a neighbor. The lid is fastened with blue rope as a hinge.

We started on our project for today, building a hay rack for feeding our sheep with hay. We used a couple of old pallets and some rest planks from the wood facade of our house. The lid plate was a rest piece that I got from thrown away building material of a neighbor. The lid is fastened with blue rope as a hinge.

The lid can be opened, and then we can put the hay in the bucket. When the lid is closed, it more or less stays where it is supposed to be.

The lid can be opened, and then we can put the hay in the bucket. When the lid is closed, it more or less stays where it is supposed to be.

At first, we had the hay rack near the fence, but then we figured they would be standing on it and then jump out from the fence. So to avoid that, we moved the rack away from the fence.

When our sheep came to inspect the new object, they were very interested in the blue rope. I wonder how the rope will survive in the coming days.

It was the first time we fed our sheep with hay. We know our sheep can eat hay, but they are not used to it. Hannah was obsessed with the blue rope. Selma is the one that will figure out how this works the first.

While we were standing there, Selma took some nibs of the hay through the slats exactly like we intended it to work. Bea followed her example but did not understand why she would do it.

While we were standing there, Selma took some nibs of the hay through the slats exactly like we intended it to work. Bea followed her example but did not understand why she would do it.

We have seen Selma figure out what to eat before the other two sisters, and then they look at how she is doing it and copy her behavior.

My wife predicted that all hay will be lying on the ground around the rack when we come tomorrow with one sheep sleeping on the lid. I hope it is not correct.

It was enjoyable to do this project! We used things we had lying, and it worked really well. It was not that warm, though. We worked outside the opening of the container. My wife got freezing feet, but my new shoes were fantastic. We could not do this in the workshop because there the pipes were lying. It had to be outside.

Thursday 4 November

Today we worked from our old home. Except for building the hay rack, we have not been active in the house. That is logical, too, because we cannot walk around in the house at all. Unless we walk beside the pipes. To reach the electricity of the fence, we walked around a little.

I was curious about how it was going, but the pipe people were finished on time. They told me the anhydrite floor will be filled up tomorrow at eleven in the morning. We will be there.

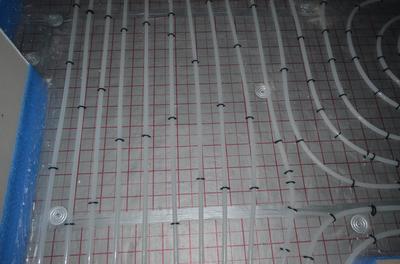

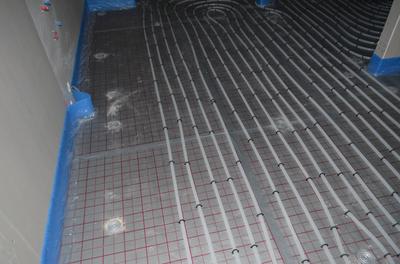

When we went to the sheep tonight, I brought my camera. I took photos of the floor so that I could go back and see where pipes were placed.

|

Here is the bottom of the staircase. |

|

|

This is in front of the hatch on the ground floor. |

|

|

Here is besides hatch and utility cupboard. |

|

|

Frontdoor is straight ahead. |

|

|

We view the hall between the workshop and the utility room with the front door in the back. |

|

|

The corner between the south wall and the front hall. |

|

|

Here we are further into the south hall. |

|

|

This is the south hall beside the utility room. |

|

|

Here we are in front of the stairs. |

|

|

This is the space where the stairs will be. |

|

|

This is the staircase with the ladder on a temporary holder. |

|

|

|

|

|

Here we are almost in the kitchen. |

|

|

With the north wall in the back, looking south with the south wall to the left. |

|

|

Looking from the east wall to the west wall of the kitchen. |

|

|

Here is the kitchen from the south with looking towards the north wall. |

|

|

The place for the woodstove. |

|

|

Livingroom. The north wall is to the right. The west wall ahead. |

|

|

Living room with the big doors to the left. |

|

|

Living room with the big door straight ahead. |

|

|

The electricity floorbox in the living room. |

|

|

This is below the ladder to the first floor. |

|

|

This is the southeast bedroom. |

|

|

The southeast bedroom. |

|

|

This is the hall on the first floor where the stairs will come. |

|

|

The staircase. |

|

|

Here is the south side of the staircase. |

|

|

Here are the pipes laid around the chimney in the hobby room on the first floor. |

|

|

The northwest corner of the hobby room. |

|

|

Here is the southwest corner of the hobby room. |

|

|

This is the utility corner on the first floor. |

|

|

The southeast wall towards the hall in the bedroom. |

|

|

This is further to the east in the bedroom. |

|

|

Here is the southwest corner of the bedroom. |

|

|

This is the door opening towards the hall from inside the bedroom. |

|

|

This is in the workshop. I decided to leave space for installing pipes to a compressor and shop vac to have outside in a utility building. |

|

|

This is the northeast corner of the workshop. |

|

|

The east wall of the workshop. |

|

|

Here is the northwest corner of the workshop. |

|

|

The west wall of the workshop. |

|

|

Here I lay out a ruler showing the distance to the hole. |

|

|

This is the other distance. |

|

|

This is the southwest corner of the workshop. |

|

|

This is below the sink in the southeast corner of the workshop. |

Here in this slideshow, there are a lot of images. I hope I don't need to look at them. If I look at them, I am probably trying to figure out where to not drill a hole. One should not do that. It is just awful to get a leakage in one of these pipes.

The squares in isolation are one by one decimeters. I can figure out where things are if it is essential.

Friday 5 November

It is Friday, and I had a half-day off. It was a sunny morning. This was going to be a beautiful day. Today it was time for pouring in that anhydrite stuff over the pipes mounted on the floors of our new house. It is an epic moment for us. We have been working towards this moment for several months. All the time, it was those giant piles of gypsum standing in the way for laying out the floor.

Today it was going to happen. At first, it would happen at 9 in the morning. Then it was changed to 11 in the morning.

I find it difficult to walk up to people and take a photo of them. Usually, you get a remark that you should not post it on the Internet. That is precisely what I am doing, and I am terrible at lying. That is why I took the first photo of the crew from a distance. It is RM Vloeren that is pouring out the anhydrite custard. Now it is not custard, but it has the consistency of very watery custard.

I find it difficult to walk up to people and take a photo of them. Usually, you get a remark that you should not post it on the Internet. That is precisely what I am doing, and I am terrible at lying. That is why I took the first photo of the crew from a distance. It is RM Vloeren that is pouring out the anhydrite custard. Now it is not custard, but it has the consistency of very watery custard.

These people arrived before us. The first thing they arranged was a cup of coffee from inside the house and our coffee machine. They were delighted with this service! They laid out a hose from their pump machine to the first floor. From there on, it was a question of waiting. The tank truck had driven off in the wrong direction, and it took some time to find the correct place.

Here is the tank finally. It is loaded with 9 and a 3 quarter cubic meters of anhydrite custard. The entire tank could take 11 cubic meters, but the driver cannot accelerate with a full load without splashing out anhydrite on the road behind him. So here he had 9 and a quarter.

Here is the tank finally. It is loaded with 9 and a 3 quarter cubic meters of anhydrite custard. The entire tank could take 11 cubic meters, but the driver cannot accelerate with a full load without splashing out anhydrite on the road behind him. So here he had 9 and a quarter.

The truck arrived and parked so that the feeder could pour gunk into the pump machine. Here are the people from RM Vloeren preparing the pump machine.

The pump machine is ready. The driver is ready to portion the pump machine in a steady stream of anhydrite custard gunk. The pump machine is radio-controlled, so the people operating it can make it pump quicker or slower.

The pump machine is ready. The driver is ready to portion the pump machine in a steady stream of anhydrite custard gunk. The pump machine is radio-controlled, so the people operating it can make it pump quicker or slower.

Here is the pipe from the pumping machine. It goes straight to the first floor via the door in the workshop.

Here is the pipe from the pumping machine. It goes straight to the first floor via the door in the workshop.

On the first floor, they started filling up the hobby room.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In the evening after work, we returned to the new house to have a look. It looked wet, completely wet.

There is simply a layer of one centimeter of water on top of the anhydrite. I poked my finger into the gunk, and it was still soft. I did not poke very deep, just gently touching the custard below the water surface. We are promised it will take 24 hours to cure, so it is okay to find out tomorrow at lunchtime if it is hard enough.

There is simply a layer of one centimeter of water on top of the anhydrite. I poked my finger into the gunk, and it was still soft. I did not poke very deep, just gently touching the custard below the water surface. We are promised it will take 24 hours to cure, so it is okay to find out tomorrow at lunchtime if it is hard enough.

We could not reach the electricity of the sheep because that is all the way to the electricity cupboard, so I had to volunteer to climb into the sheep fence with the risk of having my balls fried, but that did not happen. Not even a little nasty zap occurred. I am so lucky. My wife handed over the buckets with the food supplement, and I administered it into their food trough without giving the sheep a slight electric shock. They had eaten hay in the new hey rack, but they were primarily pooping on the lid. Such lovely animals.

It is interesting to see how many people have been involved in this project. We hired Gijs, the heating pump specialist. He hires Danny, laying out the pipes. Then the anhydrite is poured by RM Floors, but the stuff comes from a tank from R. Monsuur, but not even that is clear to me. The truck itself can be one company, and the anhydrite is mixed and pumped up in the truck by a company I don't even know the name of.

Saturday 6 November

It was a gray morning and not especially warm. I was curious how the floor had cured. I had an unrealistic fear that the anhydrite had not cured, "Oh, we forgot the active ingredient." Obviously, that is just fantasies but suppose it would happen? I could just see how someone had to scoop out the gunk again. 9 cubic meters of stuff.

Another idea was that we should not come too early to the house because it needs 24 hours to cure. So what should we do before going to the house? I had an excellent idea, go shopping for the PVC flooring.

We got several samples of floor tiles. We took these to our old home and compared them with our old natural wooden floor. Many of the samples in the shop had a green shade to them. I did not like that at all. We found one that compared very well with the floor we got in our old living room.

We decided on TFD Pro+ 1145-2 tiles. It has a pattern of a wood floor. We decided to not buy any skirting boards because we will try to make those ourselves.

We decided on TFD Pro+ 1145-2 tiles. It has a pattern of a wood floor. We decided to not buy any skirting boards because we will try to make those ourselves.

First, the anhydrite floor will be sanded and equalized, and then these tiles will be glued onto the floor.

- 12 November, they will come and measure the floor.

- 11 December the tiles will be delivered.

- 13 December, the floor will be sanded and equalized.

- 16 December, they will glue the floor.

It took the morning to settle this deal. After that, we had lunch, and then it was time to go to the new house and see the cured anhydrite floor for the first time.

They had left one surprise for us! The dish brush had fallen into the gunk in the workshop before it had cured, and now it was united with the floor. Firmly.

They had left one surprise for us! The dish brush had fallen into the gunk in the workshop before it had cured, and now it was united with the floor. Firmly.

For the rest, it looked lovely. The level had become as I had anticipated. The floor box came out a little under the anhydrite floor.

For the rest, it looked lovely. The level had become as I had anticipated. The floor box came out a little under the anhydrite floor.

It had flowed very well. There were plastic clips from the pipe here and there that had surfaced. They will be removed when the floors are sanded.

We opened all windows so that the house could dehydrate. I also put two fans to blow warm air. We will see how efficient these are.

The biggest challenge was the washing room on the ground floor. The toilet that we had standing on a pallet as a temporary solution was not smelling very well. Danny and the helper had decided to keep it while installing the pipes, but they lifted it. The sewage pipe did not close very well, and there was a stench in the entire house.

The biggest challenge was the washing room on the ground floor. The toilet that we had standing on a pallet as a temporary solution was not smelling very well. Danny and the helper had decided to keep it while installing the pipes, but they lifted it. The sewage pipe did not close very well, and there was a stench in the entire house.

We had all the rest of the pipes collected, and I found the correct pipe and made an extension ring. I put the ring on the sewage pipe coming out of the floor and fixed the extension ring with duck tape. Then we put the toilet back, and the stench was gone. That was lovely. It was not that simple, actually. At first, we tried to get the pallet back with the toilet on it. That resulted in crushing the now extended pipe against the toilet's pipe. It was challenging to fit them onto each other. I had to remove the toilet from the pallet, and only then was it possible to mount the pipe properly on the extended pipe of the sewage.

Our sheep were constantly bleating while we worked on the toilet. That was so annoying. I had been kneeling into the sewage water, so I had wet and smelly knees as well. While I worked on that, I noticed that the electricity had been disconnected. I think the RM Floors had done that. That means the sheep had been without electricity last night. You just have to be lucky, I suppose. It was perfect that I did not notice because that had made me so anxious that I had probably not been able to sleep very well.

When walking on the new floor, it felt elevated. Obviously, it is elevated because it is 9 centimeters higher. I wonder how long it will take until the new level feels like the new normal.

I saw wheel tracks that someone had been driving on the grass. The person had reversed out in the grass towards the helophyte filter. Then he drove beside the driveway with spinning wheels. I don't like it. We are putting an enormous effort into our land, and driving offroad on it is total disrespect. We gave someone a decent job for a couple of days, bringing coffee and cookies, etc. Since I know where different cars were standing at different moments, I am pretty sure I know who it was. It is just sad that my effort was not appreciated. Perhaps the problem with the stench was the trigger to this kind of behavior. We will not know. For me, this is the last time I have someone driving offroad next to my driveway. I will put up physical barriers that will damage cars if they drive off-road next to my driveway.

Before we left our new house today, we put up some ventilators to move air throughout the house, and we also had windows open. We must get the moisture out of the house as quick as possible.

Sunday 7 November

After a good night's sleep, I recovered from my grumpiness that someone was driving off-road on my land. It was going to be dry weather today, even with some small bits of sun.

So what should we do now in the house? We should plaster, but we will need to build up the indoor scaffold again to do that. There is just one small thing: The scaffold we used last time inside the house is now serving as a shelf in the container. It is not the right time to move everything from that shelf into the house because the tiles still need to be done.

This is the perfect reason to work on the outside so that the scaffold outside can be taken down. That would be grand! I still have some work to do on the roof gluing the sheet that has let loose.

- There needs to be painted on a couple of places around the windows,

- I need to look into the ventilation opening on the south wall. I will remove it and look that it is moisture-proof and then put it back.

- I need to fasten the northwest corner.

Today my wife was researching ecological paint. Specifically, paint that can breathe as it were. The idea is that we got walls that are designed to isolate while letting moisture through. We should not put the final layer of paint on the walls that undoing all that effort of letting moisture through. Obviously, our ventilation system is also designed to collect moisture, but living in a plastic bag is not good.

We came to the new house relatively late. It was much more pleasant to walk into the new house today without the sewer stench. That alone was a fantastic welcome.

My wife worked on plastering seams and screw holes, and I decided to rebuild the hatch to the space below the house. We built the first hatch on 20 August 2020.

My wife worked on plastering seams and screw holes, and I decided to rebuild the hatch to the space below the house. We built the first hatch on 20 August 2020.

There is a new extra layer on top of the previous concrete floor, and I decided to put spaces on top of the old hatch and finish off with a plate on top. One side of the hatch is resting on concrete and the other on styrofoam, and now I made the new space a tiny bit wider than the original hatch; it is possible to let the new hatch rest on the concrete. It is trickier to get the hatch from the floor, so now I also made two handles so that you can drag in those. I think that is convenient.

There is a new extra layer on top of the previous concrete floor, and I decided to put spaces on top of the old hatch and finish off with a plate on top. One side of the hatch is resting on concrete and the other on styrofoam, and now I made the new space a tiny bit wider than the original hatch; it is possible to let the new hatch rest on the concrete. It is trickier to get the hatch from the floor, so now I also made two handles so that you can drag in those. I think that is convenient.

There were sunny moments today, but most of the day, there came small showers. That was not nice.

There were sunny moments today, but most of the day, there came small showers. That was not nice.

We cannot light a fire in the woodstove because it is tucked away in the container. There needs to be moisture removed from the house. We have two fans, and we put them to work in the new house. Electric fans, not supporters. We also got windows ajar. Our windows got locks so that it is possible to have the windows ajar but locked.

I discovered two kinks in the pipe in the bathroom on the first floor. I talked to Danny about it, and he will come and fix that next week. When?

I discovered two kinks in the pipe in the bathroom on the first floor. I talked to Danny about it, and he will come and fix that next week. When?

It had been nice if it was possible to glue the rest of the roof sheets today, but it was occasionally raining every now and then the entire day. Nothing to do about it. This had been nice for fixing the outside to take down the scaffold, but it is also true that we got the Crab 48 scaffold as well; it can also be used on the first floor if we so like.

This concludes this week's effort in the house. There is more to tell, but I have been very wordy this week already, sorry about that. Next week I will probably write fewer words.

The west wall of the barn was paintedStarted preparing for painting the barnFinished plastered all walls of the barnStarted plastering the wallsBarn’s ceiling paintedPlastered the ceiling of the barnPlastering the ceiling of the barnInstalled the Murphy bedMore gypsum boards in the barnThe lamps in the hallway were installedInstalled more lamp fixturesLight installationsSea container picked upSea container soldFinished cleaning the sea container

The west wall of the barn was paintedStarted preparing for painting the barnFinished plastered all walls of the barnStarted plastering the wallsBarn’s ceiling paintedPlastered the ceiling of the barnPlastering the ceiling of the barnInstalled the Murphy bedMore gypsum boards in the barnThe lamps in the hallway were installedInstalled more lamp fixturesLight installationsSea container picked upSea container soldFinished cleaning the sea container I moved from Sweden to The Netherlands in 1995.

I moved from Sweden to The Netherlands in 1995.

Here on this site, you find my creations because that is what I do. I create.